Introduction: Most ERPs Fail Because They Don't Fit the Business — Debox Builds ERPs That Fit Your Reality

Across industries, companies struggle with:

- inconsistent processes

- manual coordination

- endless follow-ups

- Excel-driven operations

- dependency on individuals

- stalled workflows

- missing data

- inaccurate reporting

- team accountability issues

- delayed approvals

- scattered information

Most leaders assume an ERP will solve these problems.

But here's the truth: Most ERPs fail — not because they are bad systems, but because they are bad fits.

Common reality:

- teams don't use it

- the workflows don't match the business

- the ERP is too complex

- the UI is confusing

- the data model is wrong

- reporting is insufficient

- too many modules, too little adoption

- too rigid or too generic

- too many features, not enough usefulness

Debox is different.

We don't force businesses to fit software. We build ERPs around the business — engineered from your real workflows, real challenges, real people, and real operational behaviour.

The result: high adoption, high accuracy, high efficiency, and high business impact.

Why Most ERP Systems Fail (Even the Renowned Ones)

We've seen this across manufacturing, services, retail, distribution, hospitality, and project-based companies.

1. They Are Designed By Tech Teams — Not By People Who Understand Business

Most ERPs are built by:

- developers

- product teams

- system architects

But an ERP must be designed by people who understand:

- operations

- HR

- finance

- sales

- customer behaviour

- approvals

- execution maturity

- on-ground challenges

Debox ERPs begin with business clarity — not code.

2. They Force the Business to Change Overnight

Traditional ERP logic: "Here is the software, adjust your business to fit it."

Real-world logic: Teams need systems that feel natural to their workflow.

Debox ERPs evolve around:

- existing habits

- realistic execution speed

- departmental structure

- maturity level

- compliance requirements

This is why Debox ERPs achieve much higher adoption.

3. They Are Too Complex, With 100+ Features Nobody Uses

ERP bloat leads to:

- confusing UI

- overwhelmed teams

- poor adoption

- high training time

- low ROI

Debox builds lean, sharp, purpose-driven ERPs — only what the business truly needs.

4. No Automation, No Intelligence — Just Data Entry

Most ERPs are glorified databases.

Debox builds intelligent workflow systems that automatically:

- validate data

- move tasks forward

- notify stakeholders

- build logs

- escalate issues

- generate reports

- highlight exceptions

- push reminders

Automation reduces human error and increases speed.

5. No Real-World Testing or Behavioural Understanding

ERPs fail when real operational situations are not considered:

- skipped steps

- late entries

- partial approvals

- backdated information

- role confusion

- interrupted workflows

Debox tests ERPs in real-world failure scenarios, not just ideal flows.

6. Reporting & Dashboards Are Weak or Missing

Leaders need:

- real-time visibility

- operational health

- performance indicators

- bottleneck insights

- exception reports

- user-level accountability

Without reporting, an ERP is blind.

Debox builds dashboards that help leaders make decisions instantly.

The Debox Way: Business-Led ERP Systems Built for Real-World Performance

Debox builds ERPs like a consulting firm — with workflow mapping, process clarity, behavioural insights, automation logic, and strong implementation ownership.

1. Deep-Dive Business Understanding

We study:

- the business model

- operational structure

- team behaviour

- departmental dependencies

- existing manual processes

- current pain points

- compliance rules

- data needs

- future scalability

This ensures the ERP reflects exactly how the business works.

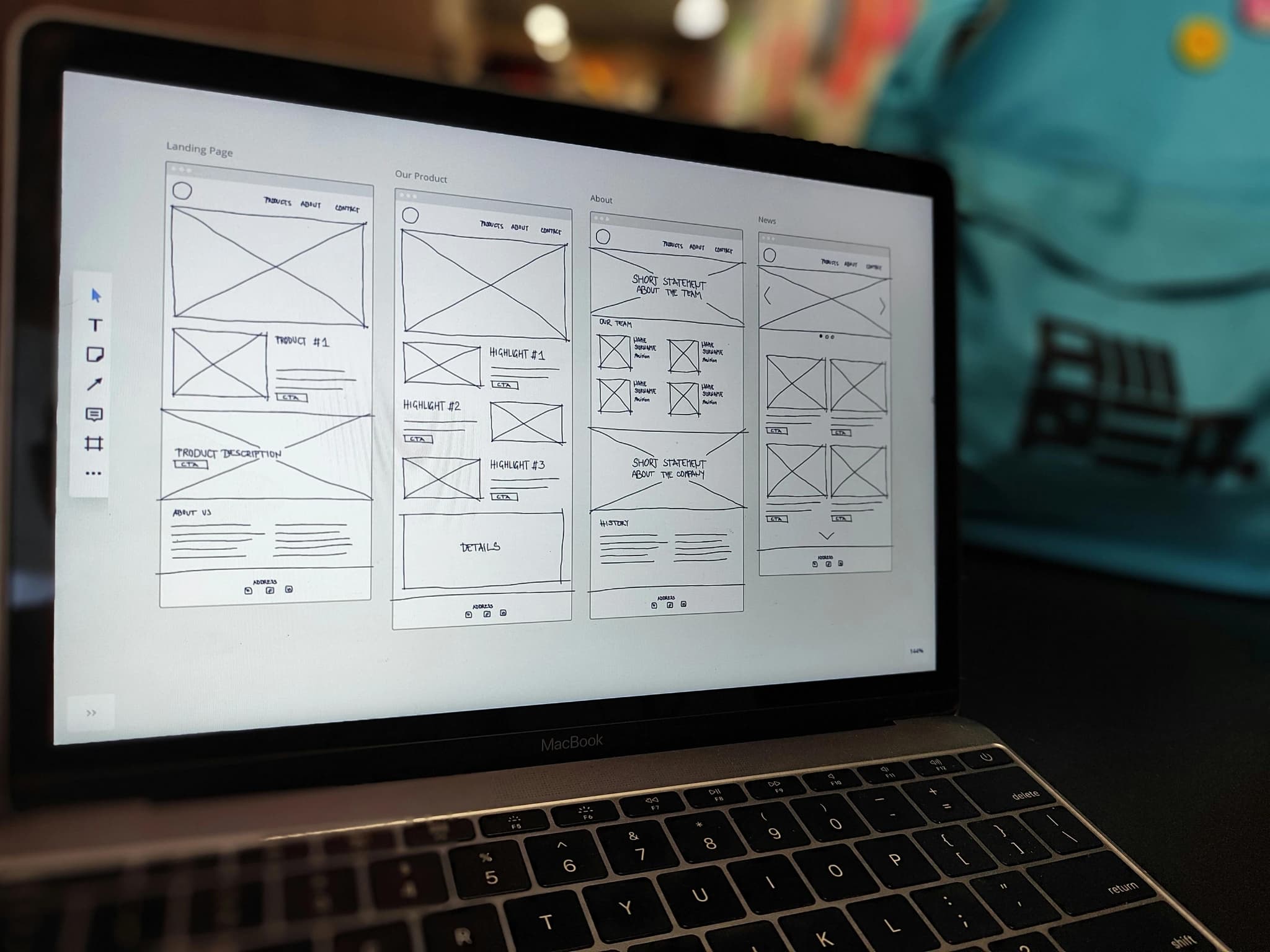

2. End-to-End Workflow Mapping

This is the core Debox differentiator. We map:

- step-by-step user actions

- checks & validations

- approval chains

- role responsibilities

- alternative flows

- exceptions

- time delays

- handoff points

- friction zones

These workflows become the ERP blueprint.

3. Module Architecture & Functional Scoping

We convert workflows into:

- modules

- sub-modules

- forms

- logs

- approvals

- alerts

- role permissions

- dashboards

- reports

- automations

- integrations

4. Data Architecture Design

Debox builds robust data models:

- clean table structures

- proper indexing

- normalized relationships

- scalable design

- query-efficient architecture

5. Automation & Control Layer

Debox ERPs include:

- auto-assignments

- automated approvals

- escalation logic

- scheduled reminders

- cross-module validations

- audit logs

- inactivity triggers

- smart workflows

- data integrity checks

Systems run themselves — people only manage decisions.

6. Role & Permission Engineering

We define:

- view-only roles

- approval-only roles

- maker-checker flows

- module-based permissions

- hierarchy mapping

7. Dashboard & Insights Layer

Debox ERPs include:

- daily/weekly performance dashboards

- module health indicators

- exceptions & alerts

- workload distribution

- team productivity

- bottleneck identification

- customer/transaction insights

8. Real-World Testing (Behaviour-Based)

We simulate:

- misuse

- wrong flows

- skipped entries

- incorrect approvals

- inconsistent data

- partial actions

- delay scenarios

Only after this does the ERP go live.

9. Implementation Ownership & Change Management

Debox does:

- training

- video guides

- refinement cycles

- user adoption tracking

- quick issue resolution

- behaviour correction

- process stabilization

An ERP is successful only when teams use it daily. Debox ensures they do.

Case Study 1: Manufacturing ERP — India

Problem:

- paper-based operations

- weak accountability

- no dashboards

- multiple follow-ups

- inconsistent data

Debox delivered:

- production tracking module

- sales-to-dispatch flow

- quality checks

- automated approvals

- exception reporting

- dashboards across levels

Outcome: Cycle time reduced 34%, accuracy improved significantly.

Case Study 2: Service Organization ERP — Dubai

Problem:

- scattered systems

- manual coordination

- low visibility

- inconsistent operations

Debox delivered:

- multi-role workflow system

- task automation

- performance dashboards

- client tracking

- billing integration

Outcome: Productivity increased 2.8×, customer experience improved.

Conclusion: Your ERP Should Not Add Complexity — It Should Add Speed, Clarity & Control

A great ERP:

- improves operational speed

- enhances accuracy

- increases transparency

- improves team accountability

- strengthens compliance

- reduces manual work

- centralizes data

- helps leaders make faster decisions

- scales with the business

- becomes the backbone of operations

Most ERPs try to be everything — and fail.

Debox ERPs focus on the essential workflows that actually drive performance.

Because technology should not complicate business. It should simplify, strengthen, and scale it.